Footer

Contact Us Today

Mail: sales@crylink.com

Phone: +86-21-66566068-300

Address:

No. 599, Huiwang East Road, Jiading District, Shanghai,China

Building 7, No.718 Baoqi Road, Baoshan District, Shanghai, China

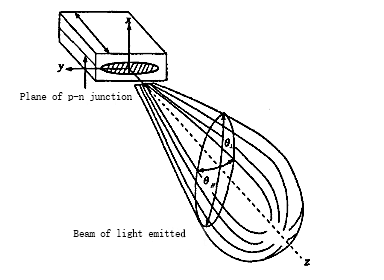

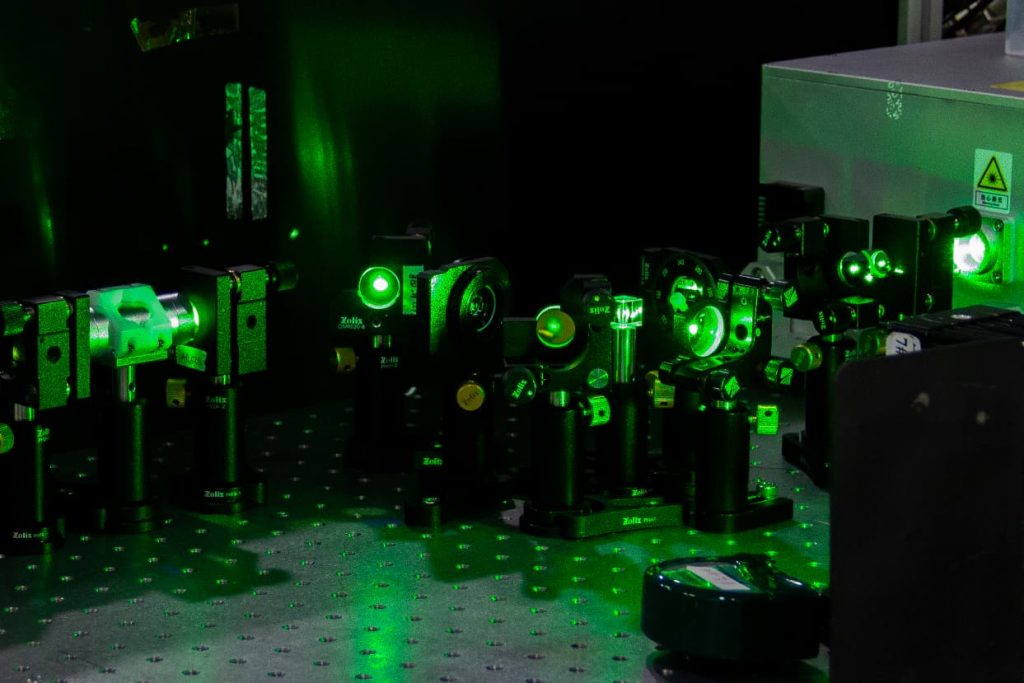

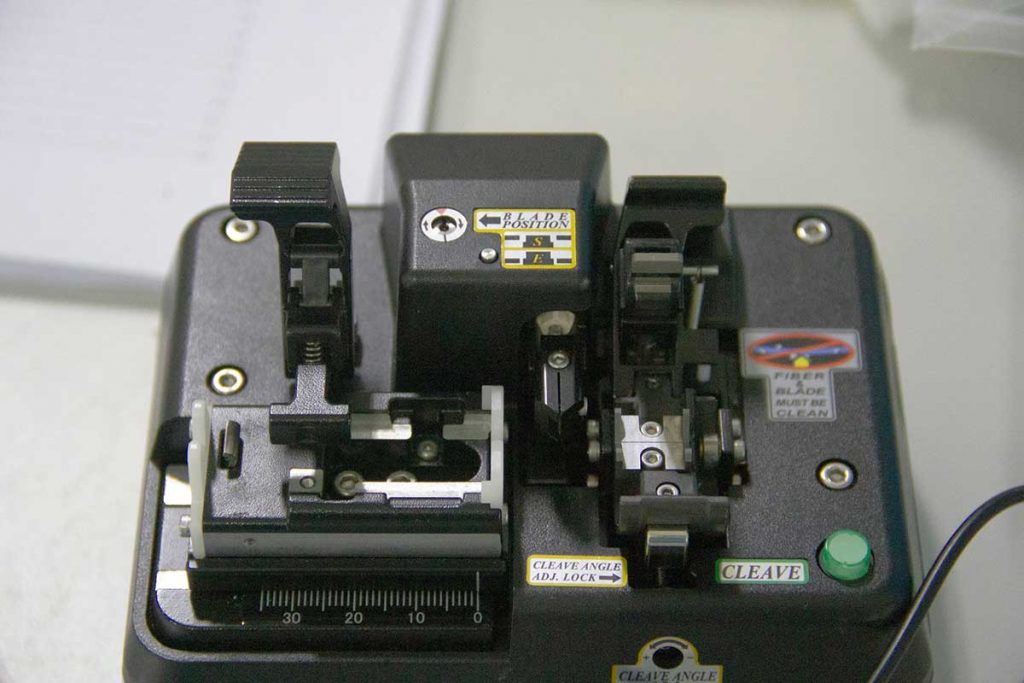

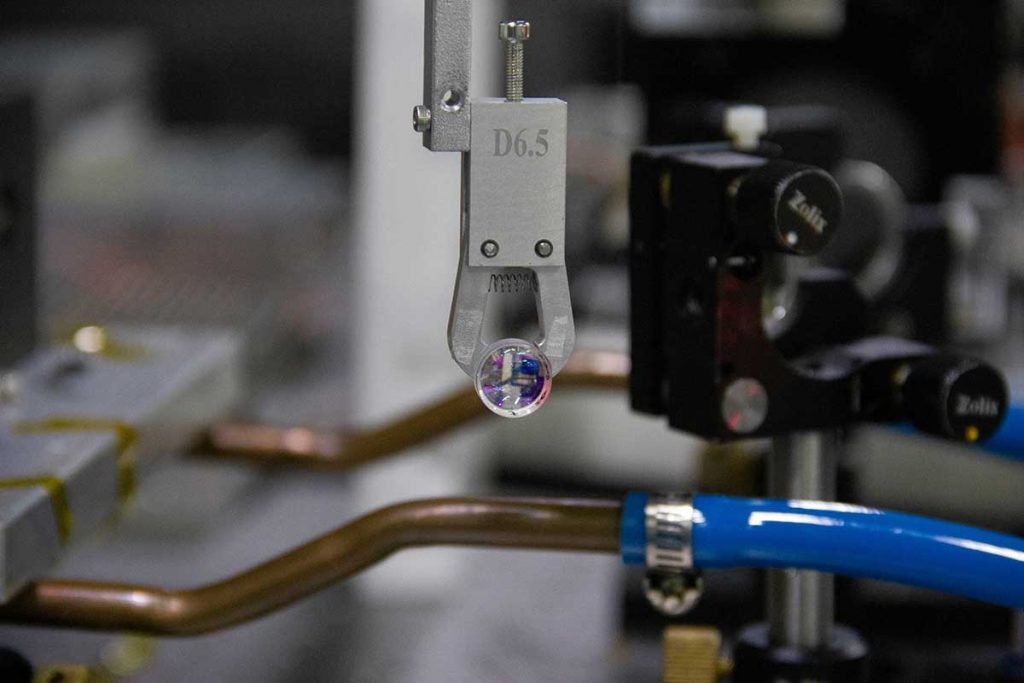

Because of the special structure of the semiconductor laser, the fast and slow-axis beam quality are not the same, and the difference is large.The method of beam splitting rearrangement is used for beam shaping, that is, splitting the slow-axis beam first, then rotating the rearrangement to reduce the size of the spot in the slow-axis direction, increasing the size of the spot in the fast-axis direction, so as to achieve the uniformity of the product of the fast and slow-axis light parameters.Our company mainly uses lens groups to shape light beams through optical design.

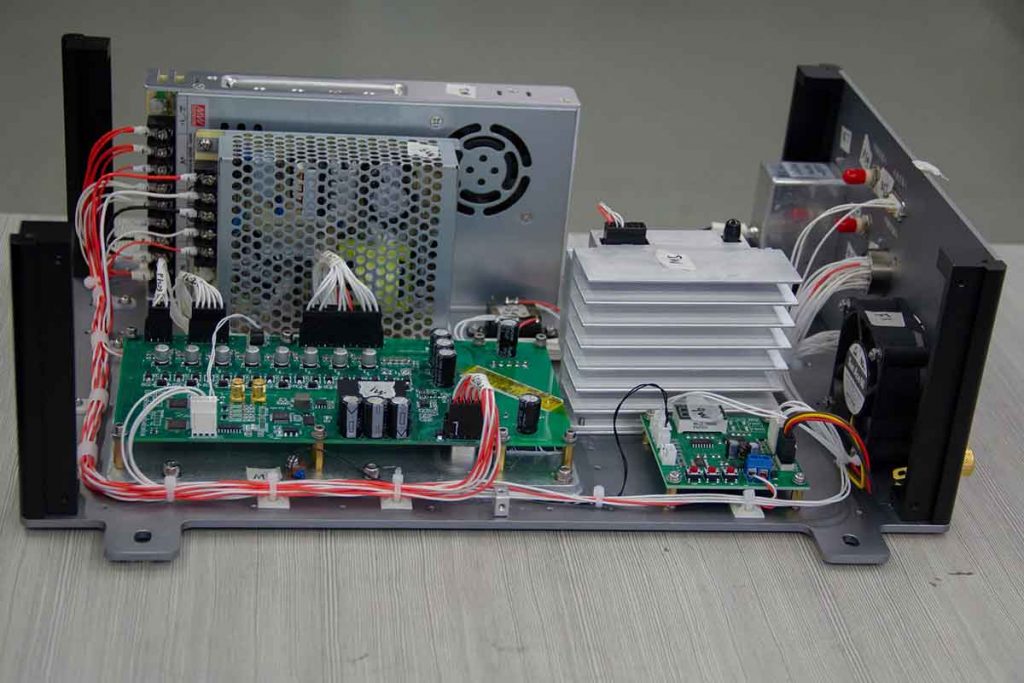

Our company mainly uses VBG, PDH and other technologies to lock the laser wavelength.

High-power and high-brightness fiber-coupled semiconductor lasers based on multi-single-tube chips are ideal for achieving high beam quality and high brightness requirements.This is mainly due to the high beam quality, good heat dissipation, stable performance and easy Large-scale integration and other advantages, can be efficiently coupled to a small core diameter multimode fiber to obtain high-brightness laser output.

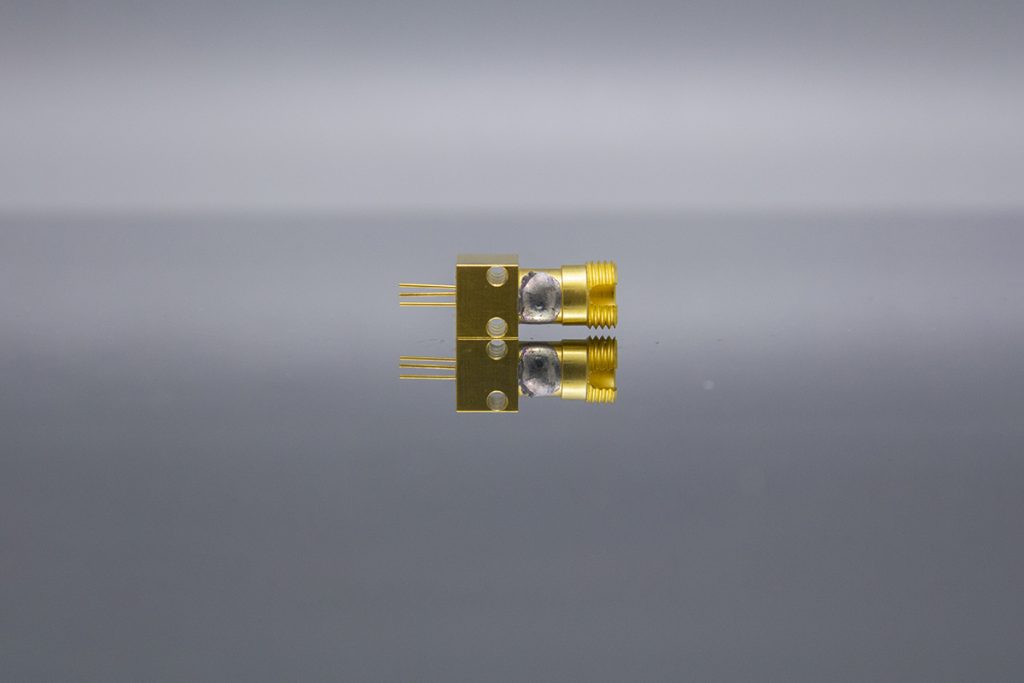

Coaxial laser is packaged by three-gun annulus welding

Other lasers are packaged using parallel seam welding technology

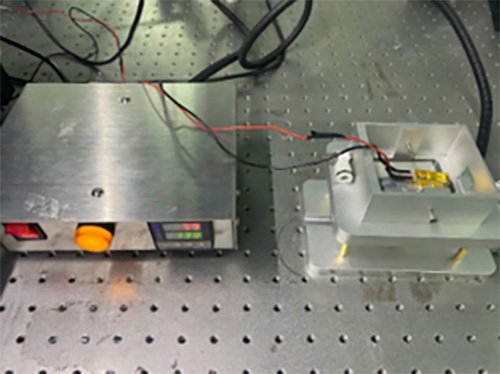

LD Welding

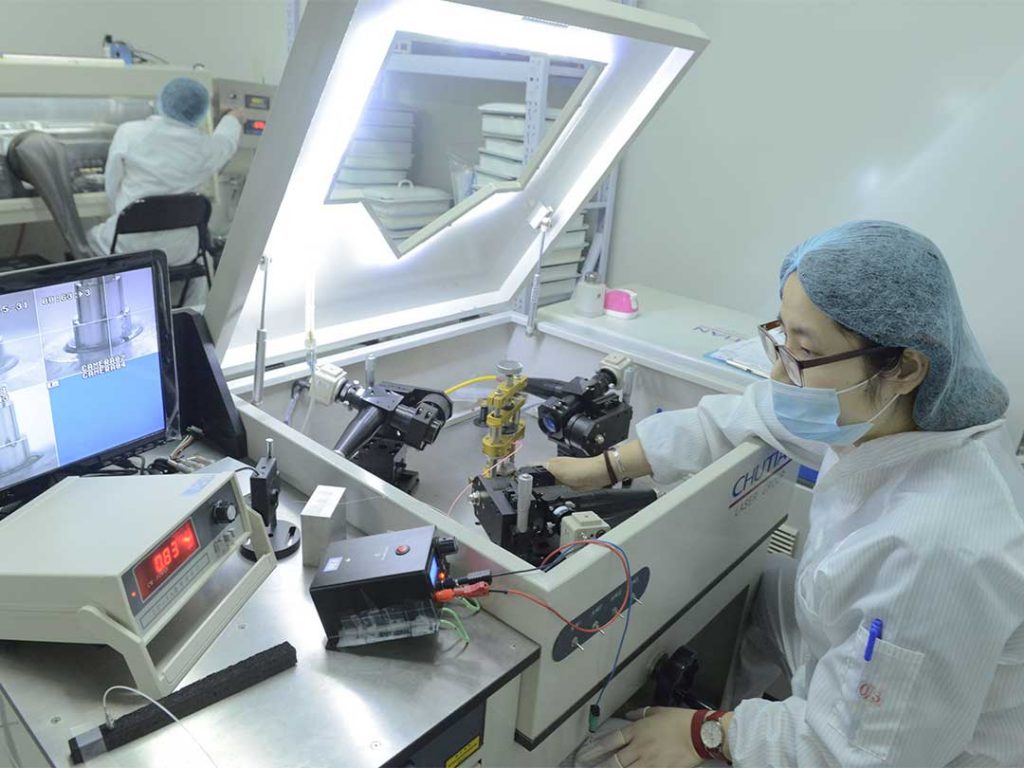

Thermostat

Electrode Bonding

Ultrasonic golden wire ball welder

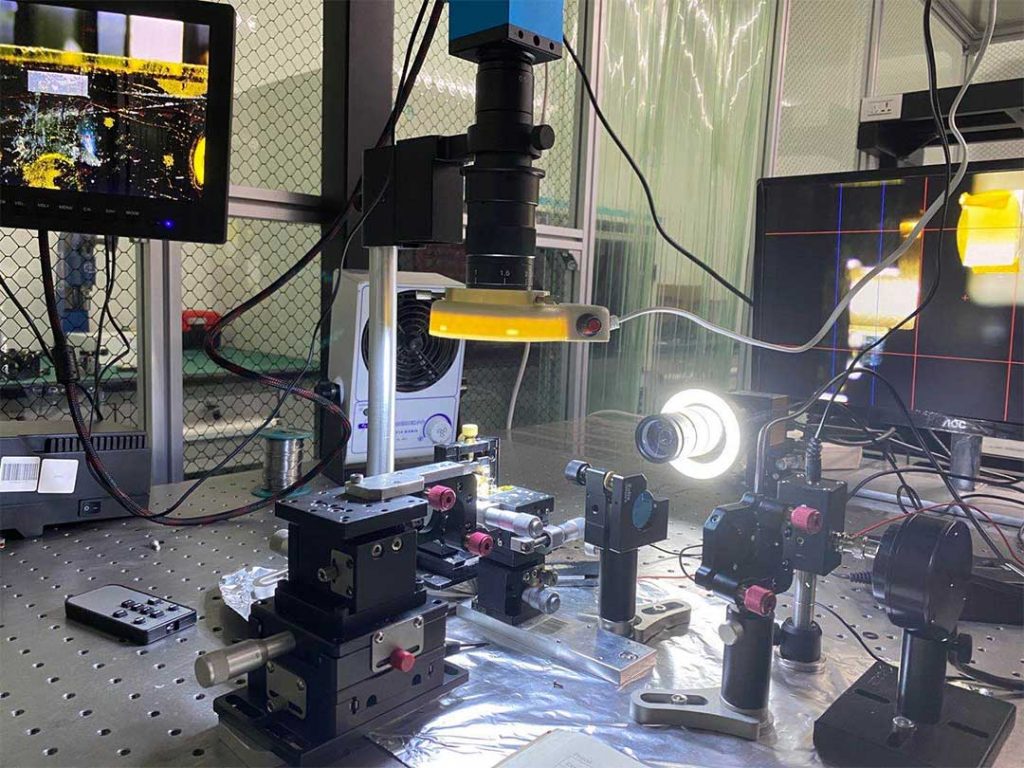

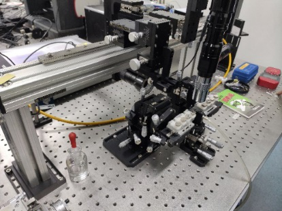

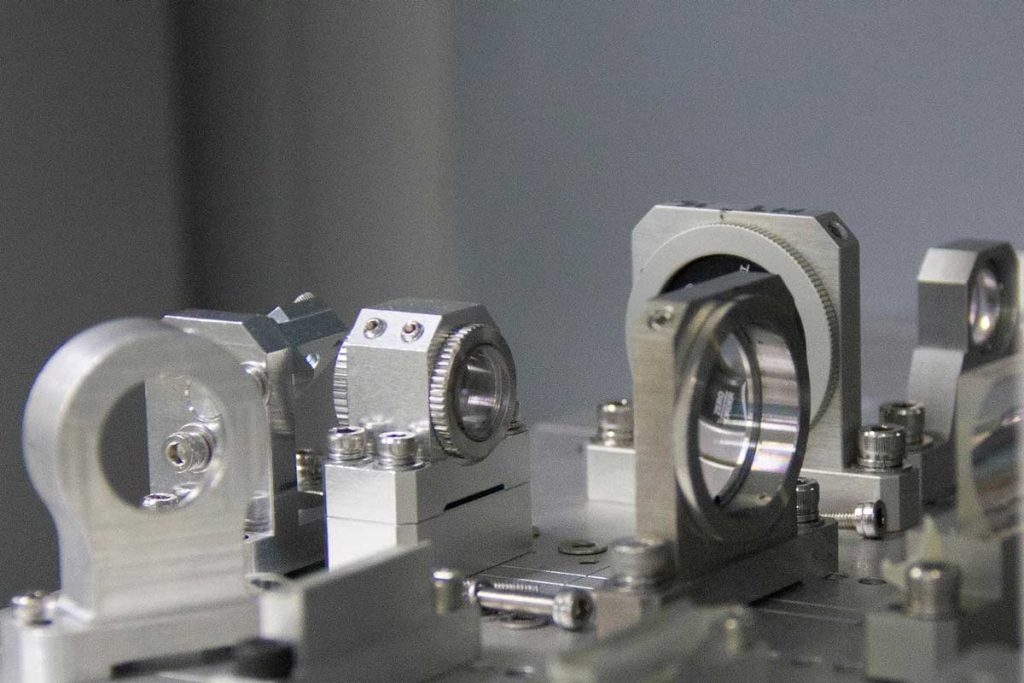

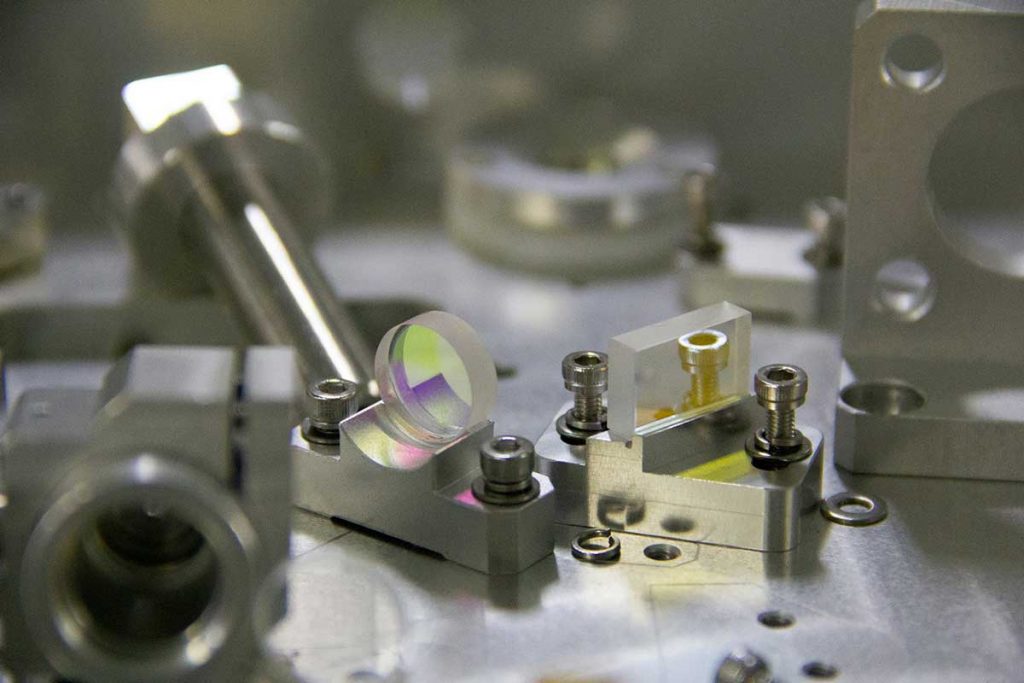

Cavity Adjustment

Ultra precision adjustment frame

Optical Device Welding

Thermostatic platform

Beam Expanding

Alignment adjustment

Ultra precision adjustment frame

Laser Packaging

Laser charging and exhausting

Parallel seam welder

Three-gun spot welder

Mail: sales@crylink.com

Phone: +86-21-66566068-300

Address:

No. 599, Huiwang East Road, Jiading District, Shanghai,China

Building 7, No.718 Baoqi Road, Baoshan District, Shanghai, China

Leave a Reply